Design is important – but there’s so much more our team can do to enhance your promotional merchandise.

One of the easiest and most impactful ways we can take your labels, tags, bags, boxes, and cards to the next level is to use a finish that will highlight its best design qualities and add an extra bit of pizazz to your brand, too.

With so many options on the table, it can be difficult to know where to start. Here’s a brief introduction to the most common finishes available here at Hallmark Labels, and some guidance on when you might want to consider each of them within your own strategy.

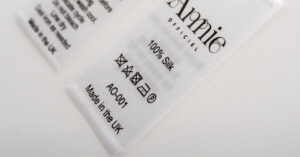

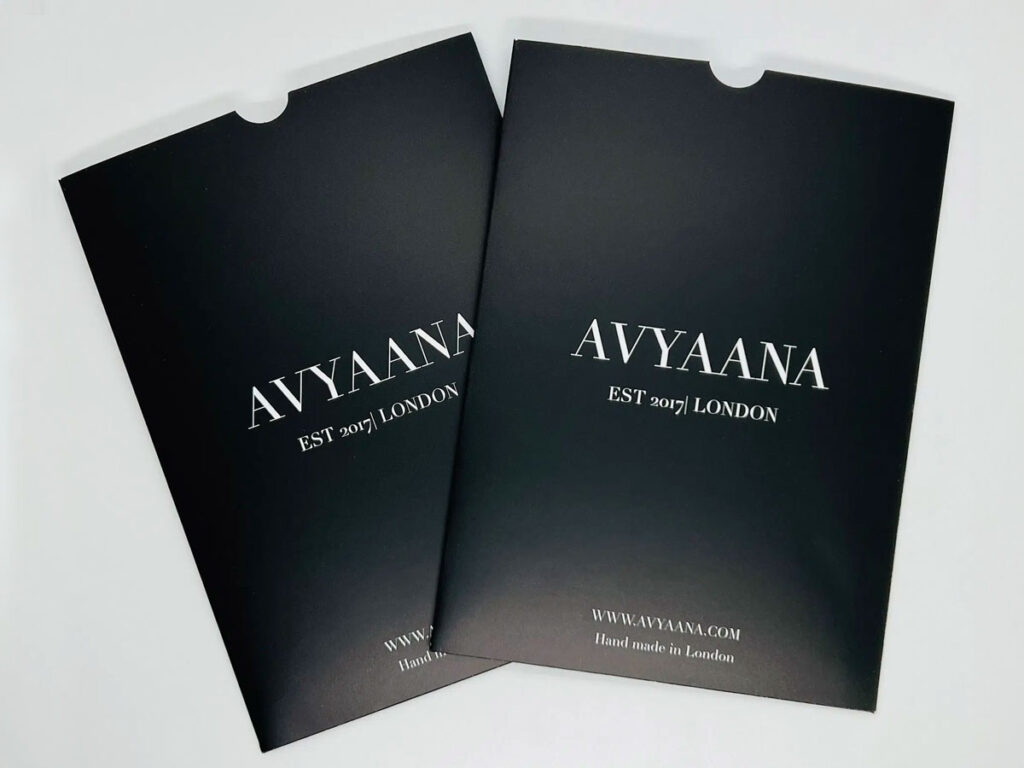

Foiling

Hot foiling, or foil printing, is a technique that uses heat and pressure to add a metallic UV coating to part of your printed item. It’s designed to highlight a particular design element, not cover a large surface area – so the trick is to use it carefully and sparingly to bring an interesting part of your design to life.

Foiling looks particularly smart when applied to the font on swing tags and/or merchandise with finer, more delicate illustrations. Gold and silver are the standard colour options here, but a range of shades are available to suit your requirements. We particularly love white foil on a black board, or a white toner, which delivers a more matte look. Foil printed products are guaranteed to boast a more premium look, so are a great way to complement a luxury brand.

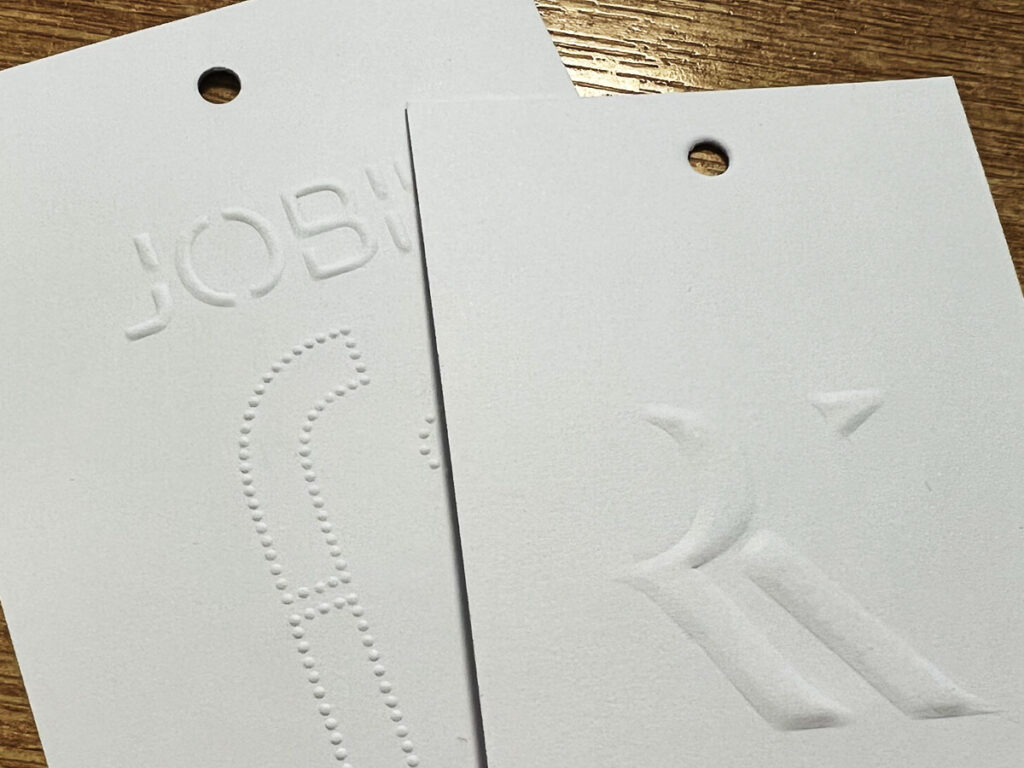

Embossing

Embossing uses a custom-made male die or roller to create a raised design. Embossed printed labels and stickers look and feel a lot more regal than their 2D counterparts; they boast a truly distinctive finish with a fascinating texture. They lend themselves particularly well to wine bottles, luxury food packaging, and high-end cosmetics.

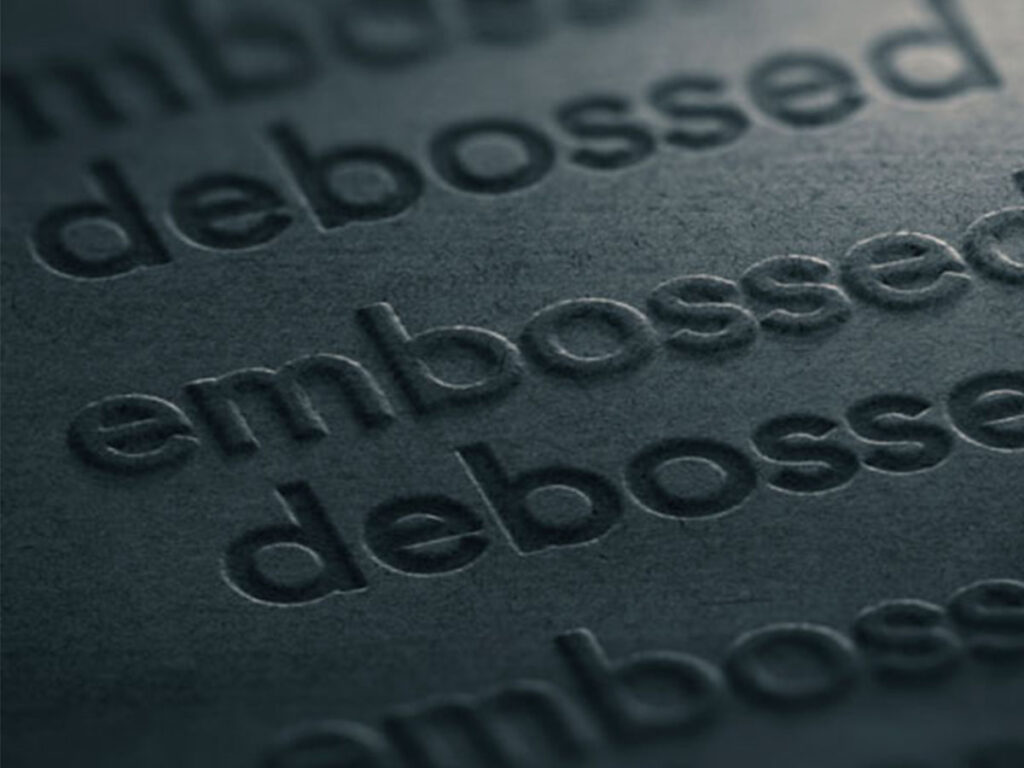

Debossing

Debossing uses recessed designs to create that sought-after, multi-dimensional pattern that immediately makes your labels a lot more tactile. While it naturally creates a ‘flatter’ effect than embossing, debossing adds a touch of class that is hard to replicate. Why not experiment with both embossed AND debossed techniques on the same piece?

Gloss/matte lamination

Laminating adds a layer of protective coating to the printing surface, usually with a type of plastic. Regardless of whether you opt for a glossy or matte finish, lamination will improve the robustness and waterproof qualities of your product, not to mention create a more dramatic contrast between colours.

Spot UV

You might also see this technique referred to as spot varnishing, spot lamination, spot gloss or simply as UV printing. Much like foiling, spot UV is used to draw attention to a small piece of your design. It works by applying polymer to the area with a flexo plate, then exposing it to UV light, which dries and solidifies it with a glossy finish. Spot UV is usually applied at the very end of the printing process.

Clear coating

This is very similar to spot UV. The difference is, the technique is carried out with digital equipment, meaning it is faster and therefore a fraction of the price!