It’s been a long time coming – but it seems like the major retailers are finally shifting from plastic bags to their paper counterparts!

Marks and Spencer (M&S) recently announced that, after a successful in-store trial in January, it will be swapping its plastic bags for paper-based alternatives.

Now the chain has admitted that paper bags do in fact require more energy to produce and are heavier to transport, leaving some people wondering how such a move will in fact be any better for the environment. But the team at M&S assures us that they have been working closely with the University of Sheffield to produce a type of paper bag that is manufactured using only renewable energy, which should go some way to offsetting any additional carbon emissions.

Research supports M&S’ claim that each bag can be used up to 100 times before it becomes worn out. The bags can be recycled thereafter, so won’t pose a threat to wildlife once they’ve been disposed of, or be stuck in landfill for decades to come. These bags are also water resistant and easy to fold, making them a practical solution for shoppers as well as a largely eco-friendlier one (this is just as important, after all, as customers don’t want to be inconvenienced by thin, weak bags that are not fit for purpose).

M&S isn’t the first large-scale business to roll out such a change. Morrisons, Waitrose, Aldi already use paper bags for customers, although many of these companies do still offer plastic bags as an option.

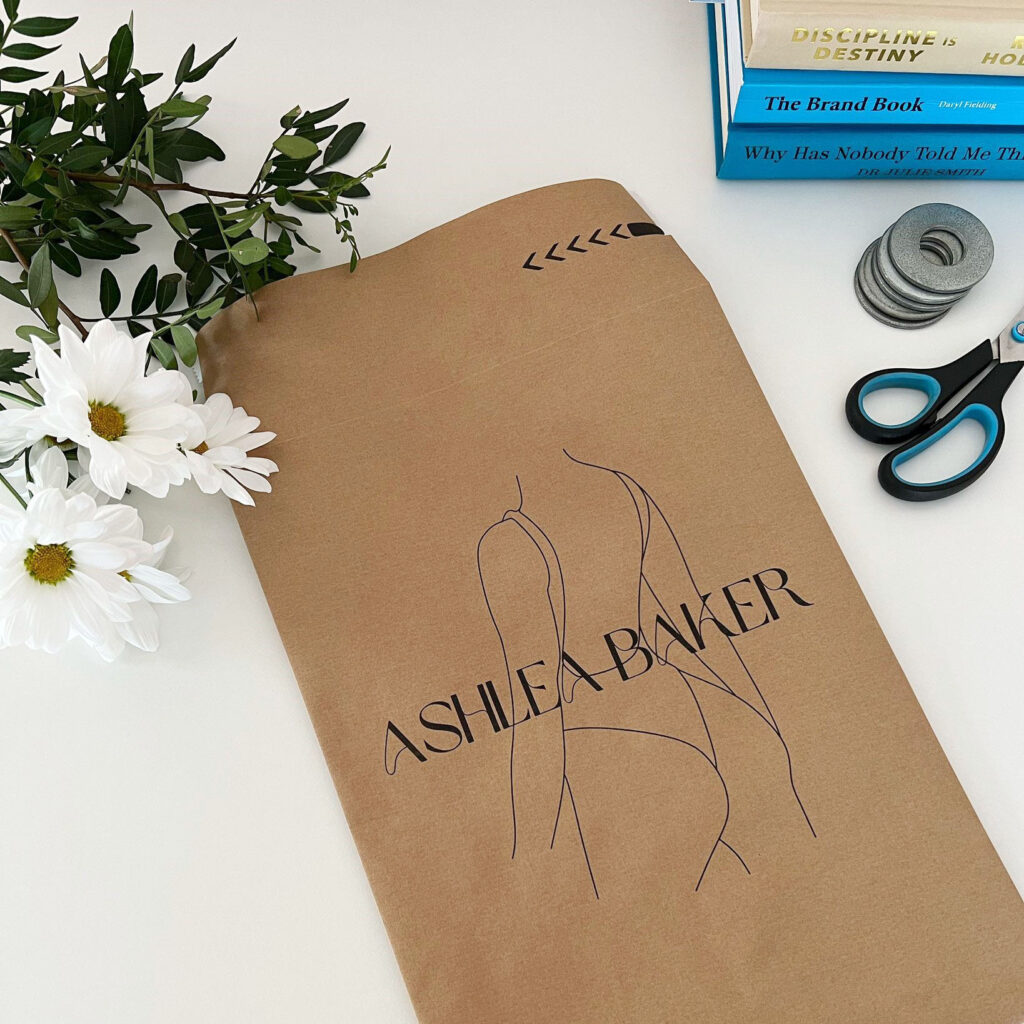

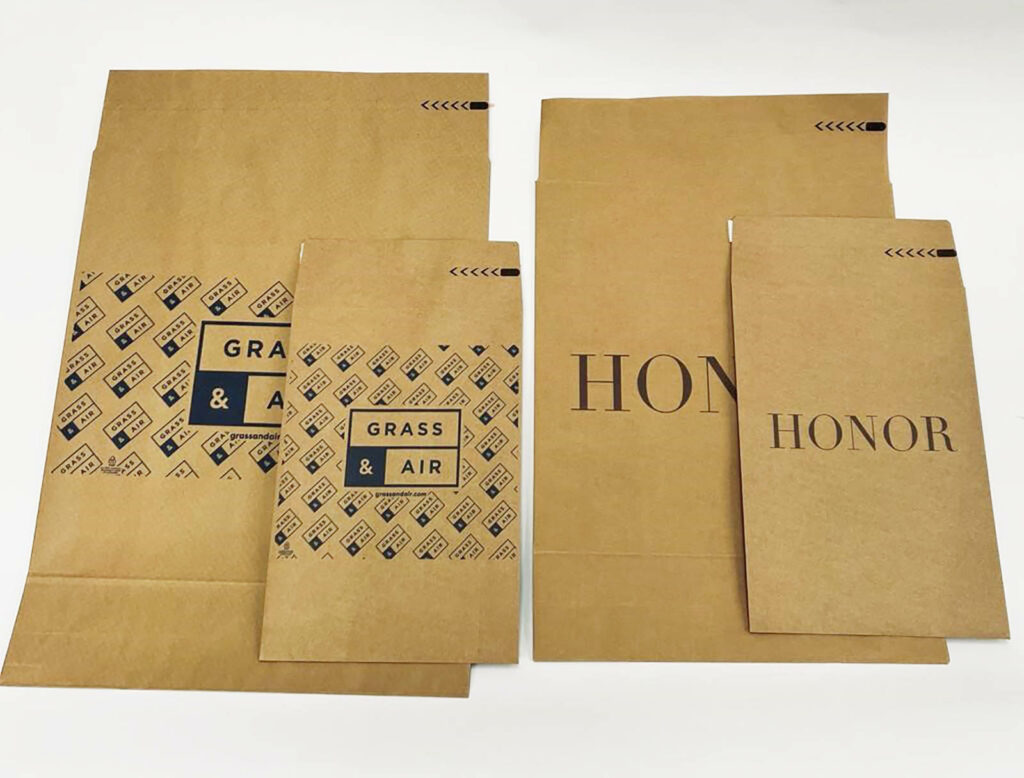

We’ve noticed that our own client base is eager to explore the benefits of custom printed paper bags, too, which is why we have expanded our range to offer an even more comprehensive selection of bespoke retail bags. Our retail bags blend the best possible mix of style and durability, and we always ensure that the materials we use to create these products are responsibly sourced, fully recyclable, and manufactured in a way that causes the least possible damage to our environment.

All bags can be printed with your own design – and we offer an in-house design service for businesses that don’t have the time or the resources to come up with something unique themselves. The standard lead time on our custom printed bags is around 4 weeks, but we do offer an express service at an additional charge that will ensure you receive your products within just 10 days. So, whether you’re planning ahead to transition to paper, or you’re after some last-minute orders to support your new branded merchandising strategy, we’ve got an option to suit your timeframes and of course your budget.

Elsewhere in our collection, we also offer paper mailing bags and mailing boxes, not to mention hard-wearing branded boxes. Get in touch to learn more and place your order!